確かな技術と品質で選ばれる抜型

BUSINESS事業案内

抜型

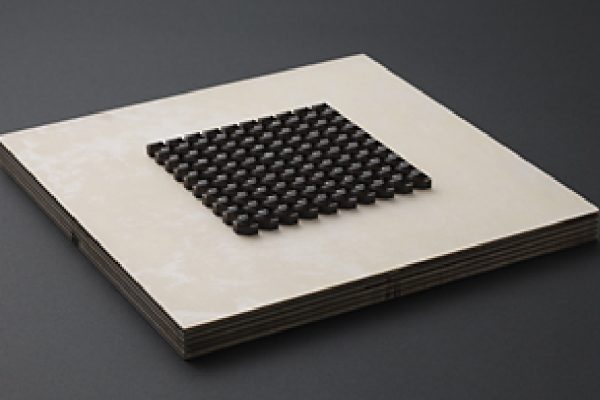

最新鋭のシステムと熟練した技術で、ビク、ピナクル、彫刻型など、お客様の多様な刃型の製作のニーズに幅広く対応しています。

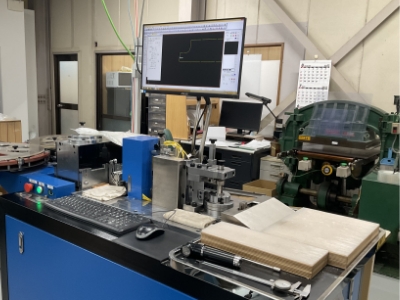

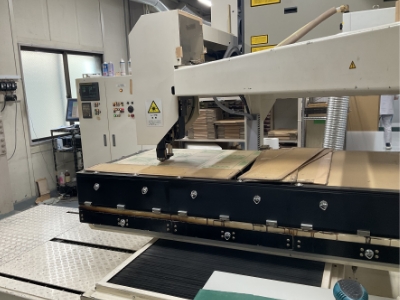

主要設備

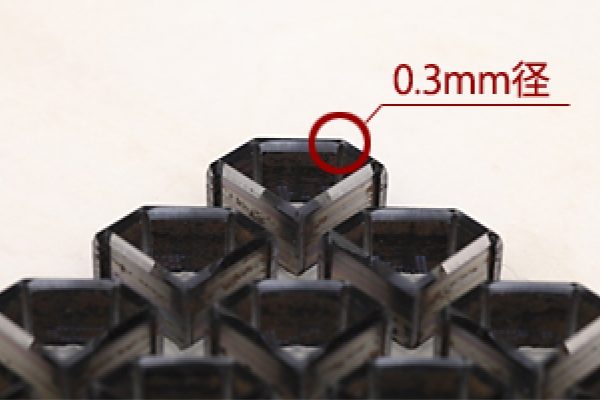

CADの製図データを基に、レーザー自動刃曲げ機など設備機械も進化し、ビクからピナクル、超精密な彫刻刃型まで短納期、高精度な刃型の製作が可能になりました。

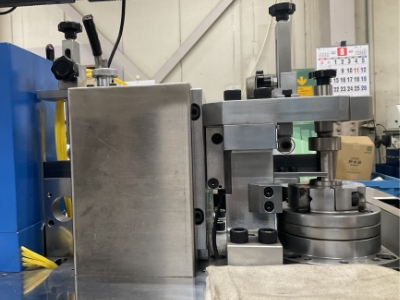

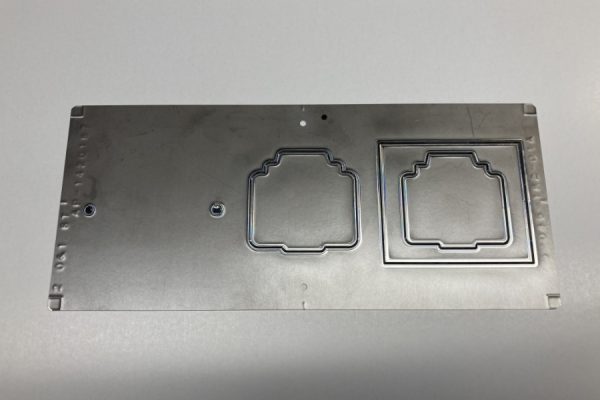

治具の作成

抜型加工した部材の作業を誘導する治具も製作しています。治具は、製品ごとに型や使い道が違いますので、お客さまのニーズに合わせてオーダーメイドでご提供いたします。

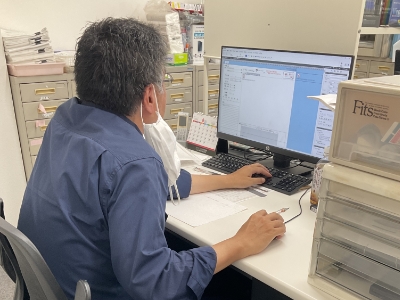

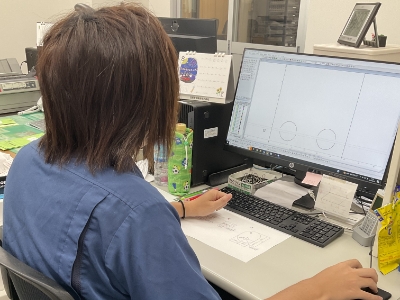

型の設計・測定

CADシステムによる設計で、設計前期段階において詳細な設計検証を行うことで、より精度の高い抜型設計を行います。また、高い精度が要求される刃型の製作後、測定顕微鏡を使って、設計通りの仕上がりかどうかを確認します。

COMPANY会社案内

会社概要

| 商号 | 株式会社 原抜型製作所 |

| 代表者 | 代表取締役 谷口 祥一 |

| 所在地 | 東京都墨田区東向島6丁目50番8号 |

| 連絡先 | TEL:03-3618-0053 FAX:03-3616-7736 |

| 設立(創業) | 昭和60年4月 |

| 従業員数 | 5名(2023年8月現在) |

| 資本金 | 1000万円 |

| 営業品目 | 精密ビク型、ピナクル型、精密彫刻刃型、その他抜型刃一式 |

募集要項

| 募集職種 | 抜型設計製造 |

| 募集期間 | 2024年4月末まで |

| 応募資格 | 高卒以上、未経験者歓迎 |

| 雇用形態 | 正社員 |

| 勤務地 | 東京都墨田区東向島6丁目50番8号 |

| 勤務時間 | 平日9時~18時(休憩1時間) |

| 休日・休暇 | 土日祝、有給あり |

| 給与 | 要相談 |

| 福利厚生 | 交通費支給、健康診断、制服支給 |

NEWS新着情報

CONTACTお問い合わせ

異素材・多階層など、複雑な型でも設計からご相談承ります。

お気軽にお問い合わせください。